Polymer Materials Make Solar Thermal Systems More Sustainable

Researchers Prove Environmental and Economic Potential

Within the ExKoll project, the Durability Analysis Group at Fraunhofer ISE investigated the economic feasibility of polymer collectors and performed life-cycle analyses. The experts found that in comparison to standard flat collectors, mass-produced polymer collectors perform better economically and ecologically.

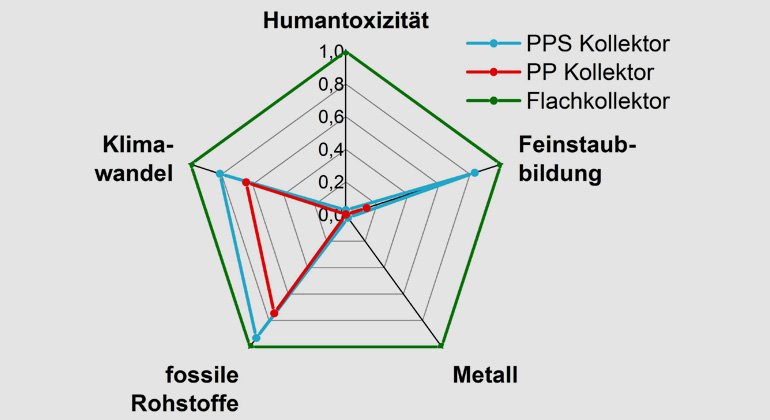

For the environmentally friendly production of collectors, the scientists considered both high-performance plastics and simple, standard plastics and assessed their suitability in solar thermal systems. Comprehensive investigations on how to increase durability and reliability as well as economic feasibility studies formed the basis of the life cycle analyses. The energy and raw material flows of the promising collector concepts were compared with those of a conventional flat plate collector with an aluminum-copper absorber. “The results of the comparison clearly show that the polymer collectors have a lower environmental impact than comparable standard flat plate collectors,” stated Michael Köhl, project leader at Fraunhofer ISE. “We determined differences of up to 65 percent.”

Also when considering the categories which have the largest effects on the environmental footprint, that is human toxicity, fine particle pollution, fossil fuels, climate change, exploration and extraction of metals, we found that the impact of the conventional flat collectors is greater in all five categories. Plastic collectors not only show a large environmental potential. An economic feasibility study revealed that alone in the production, plastic collectors can achieve cost savings of up to 50 percent compared to standard collectors. This result is particularly interesting for companies that already manufacture plastics and who want to widen their range to include collectors.

Future research is to focus on optimizing the supply and distribution chain of polymer collectors. The goal of the research is to decrease costs further and to promote plastics as an alternative material in solar thermal technology. A new Task of the Solar Heating and Cooling Program of the International Energy Agency (IEA SHCP), whose topic is cost reduction, offers an ideal platform for pursuing this goal. The Task is led by Fraunhofer ISE and shall start its work in summer 2015 to develop further strategies for reducing the costs of solar thermal applications.

About the ExKoll project

In the ExKoll project, which was sponsored by the Federal Ministry for Economic Affairs and Energy from 9/2012 through 12/2014, the use of extrusion for manufacturing polymers was investigated. A market analysis was conducted to determine potential markets for extruded plastic collectors. In addition, accelerated aging tests were carried out to adapt and optimize the polymer materials. These are performed under deliberately heightened levels of UV radiation, temperature and humidity.