AgriPV for viticulture – protection against climate damage and high additional yields

Late frosts, hot spells, extreme drought and heavy rain endanger the sensitive grapevines.

The temperature increase caused by climate change is already clearly noticeable in viticulture: the vegetation period of the plants, budbreak and vine blossom tend to shift earlier into the year. However, earlier development also increases the risk of damage from late frosts, which hardly change in time. Later in the year, heat waves and extreme drought events threaten the vines.

Both frost protection measures and irrigation as well are expensive. If water is not available on site, it must first be provided and transported at great expense.

Frost, heat and drought are not the only threats to the vine. For grapevines, which prefer a warm temperate climate with a low number of extreme weather conditions, heavy weather events with extreme forms of precipitation (sleet, hail, heavy rain) also pose a threat. Heavy rains and prolonged summer rains favor fungal infestation (powdery mildew) of the vines during the summer months and lead to crop failures.

AgriPV installations protect the vines

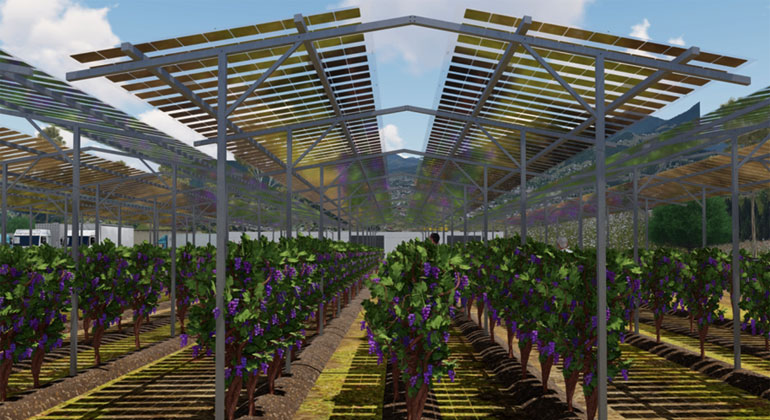

Highly elevated AgriPV installations have proven themselves many times in fruit growing and have shown that effective protection against climate damage is possible without lasting yield losses in pome fruit (e.g. apple orchard in Kressbronn/Lake Constance). In the case of berries, additional yields of over 8% have been observed in large plantations. Such AgriPV installations are now also being planned in viticulture to protect against crop damage. Our figure shows the simulation of such an installation in a vineyard.

Electricity yields finance the installations

The expenses for protection against climate damage in viticulture are already a significant cost factor today. Nevertheless, a reliable protection against hail, heavy rain or too extreme heat can usually not be achieved. The AgriPV systems of GridParity, on the other hand, finance themselves within a few years through the high electricity yields.

Depending on the design, they also offer protection against hail, heavy rain and heat as well as mildew. Protection against post-frost is also usually provided. Additional significant advantages are the limited evaporation and thus the lower water consumption.

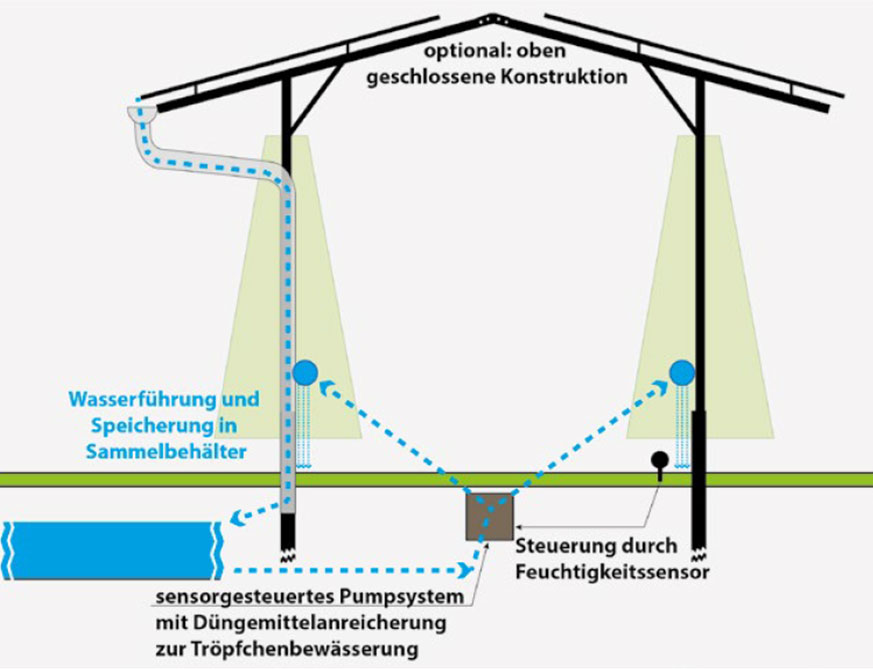

Thanks to drip irrigation, which can be installed at little extra expense, and water management (see illustration), it is even possible to store a surplus of rainwater in some cases. The use of spraying agents can also be reduced by up to 80% (empirical values from pome fruit cultivation).

Variable design and adaptation to terrain profiles

Both the dimensions and the design of the plants are carried out digitally according to the already existing or planned row and plant spacing as well as the terrain profiles. The implementation in the production plans is then carried out on the basis of static analyses. Each plant is manufactured individually in fully automated processes at low cost.

High electricity yields despite PV module transparency

Since vines are usually planted in small distances, the AgriPV can be adapted very well to the plant rows so that a relatively large density of the PV installation can be achieved.

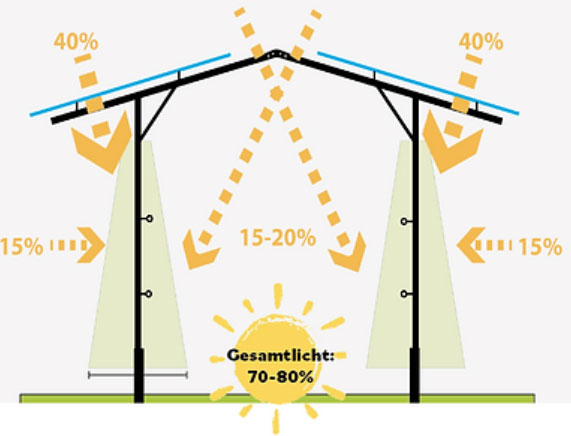

Despite the need for climate protection, a high light yield is indispensable for many vines. The open design of the racks and the transparency of the modules allow a total light quantity of 70-80% due to the light coming in from all sides. This corresponds to the amount of light that is also achieved under protective film tarpaulins. Given the sharp increase in light intensity caused by climate change, this is sufficient for most vines.

AgriPV modules are produced in AGORA factory in Slovakia in different degrees of transparency. In case of a higher light requirement, PV modules with higher transparency are also available.

Conclusion:

The installation of AgriPV systems is an economically interesting measure to protect grapevines from climate damage. The investment is financed within a few years by the high electricity prices in relation to the electricity production costs by the AgriPV system of only about 5 cent per kWh. In most cases, the electricity can be used directly in the winery for the operation of technical equipment, vehicles (e.g. e-driven tractors) and cooling systems.