Machine learning fast-forwards solar cell design

Researchers in Australia have harnessed AI to produce solar cells from the mineral perovskite in just a matter of weeks, bypassing years of human labour and human error to optimise the cells.

Study lead author Dr Nastaran Meftahi, from RMIT University’s School of Science, said teams of researchers worldwide were racing to make perovskite cells, which were cheaper than silicon and – thanks to recent advances – now stable enough for long-term commercial use.

“Until now, the process of creating perovskite cells has been more like alchemy than science – record efficiencies have been reached, but positive results are notoriously difficult to reproduce,” she said.

“What we have achieved is the development of a method for rapidly and reproducibly making and testing new solar cells, where each generation learns from and improves upon the previous.”

Members of the Centre of Excellence in Exciton Science based at RMIT, Monash University and Australia’s national science agency CSIRO have removed human error from the equation in rapidly innovating solar cells with AI.

Using data generated by the team’s system, Meftahi, Dr Andrew Christofferson and Professor Salvy Russo from RMIT developed a new model of machine learning.

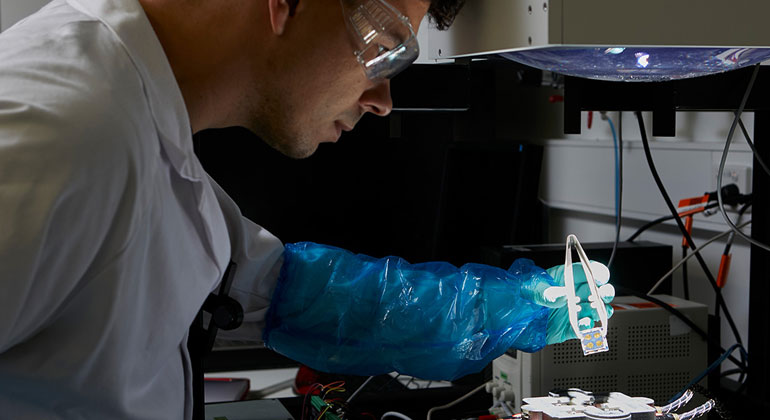

With a multimillion-dollar automated system for solar cell manufacturing being built by Dr Adam Surmiak at Monash University, the model will be capable of predicting huge volumes of promising chemical recipes for new perovskite solar cells.

Surmiak and Professor Udo Bach at the Australian Centre for Advanced Photovoltaics and CSIRO will lead this new facility, which is currently under construction.

Designing reproducible solar cells

The team’s combined work, published in top journal Advanced Energy Materials, has resulted in reproducible perovskite solar cells with power-conversion efficiencies of 16.9% – the best-known result manufactured without human intervention.

“A reproducible 16.9% power-conversion efficiency is better than an irreproducible 30%,” Meftahi said.

Reproducibility has been a major challenge for human-led and other reported AI-driven perovskite cell design and development processes.

“Critically, our machine learning model represents the starting point for further optimisation, both in terms of power-conversion efficiency and stability.”

Surmiak’s team designed and characterised 16 new solar cells never seen before using his novel setup, and Meftahi used these cells to predict the properties of 256 new solar cell recipes.

“Then Adam, with the help of his group, developed 100 new solar cells and that let me predict the properties of 16,000,” Meftahi said.

“At Monash, they’ll soon be able to make 2,000 unique solar cells per day. We’re quickly getting to the stage where we’ll be able to predict the properties of millions of different cells.

“And you can’t do that with anybody else’s machine learning model, because you’d need additional information before you’ve made the cell.”

Next steps

Meftahi said the machine-learning model and automated system can also potentially be used to crunch the numbers and run tests on other types of solar cells, including those made with silicon or organic materials.

“We are keen to work with partners in industry to further test and prototype our work so that it can be possibly commercialised in a range of applications,” she said.

Support for the research

The Australian Renewable Energy Agency (ARENA), the Australian Centre for Advanced Photovoltaics (ACAP) and the Australian Research Council (ARC) through the ARC Centre of Excellence in Exciton Science supported the work. The researchers also acknowledge the support of the Melbourne Centre for Nanofabrication, Monash X-Ray Platform and Monash Centre for Electron Microscopy.

- ‘Machine learning enhanced high-throughput fabrication and optimisation of quasi-2D Ruddlesden-Popper perovskite solar cells’ is published in Advanced Energy Materials (DOI: 10.1002/aenm.202203859).