Safe and Efficient Transport of Hydrogen

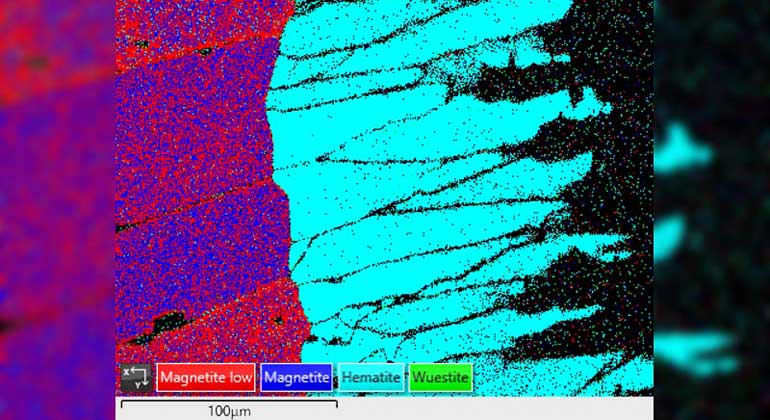

Energy in Iron and its Oxides

Transporting green-generated energy in form of iron: That is the vision of a project funded by the German Federal Ministry of Education and Research and coordinated by UDE. Hydrogen produced by solar energy, a chemical reaction and transport in metal form lead to a sustainable cycle to produce hydrogen in places and at times when it is needed. Working with partners from Clausthal and Bremen as well as associated industrial partners, the team wants to develop a concept for its implementation on an industrial scale.

Hydrogen (H2) is highly flammable, highly volatile and embrittles many materials. This combination has made transport costly and inefficient to date. One possibility is to store and transport hydrogen as ammonia. A team led by Dr. Rüdiger Deike, professor of metallurgy and forming technology at UDE, on the other hand, is pursuing an approach whose cycle would look like this, for instance:

In a place offering high solar radiation and easily available water resources, e.g. on the African continent, in Australia or South America, photovoltaic systems supply electrical energy. This is then used to split water into oxygen and H2 in an electrolysis. Now, all that is needed is a subsequent chemical reaction to reduce iron ore (iron oxide) to obtain iron – which is shipped as mini briquettes or pellets without any environmental risk. At the destination, the reverse reaction is initiated to obtain hydrogen and iron oxide again.

Although the underlying iron-steam process has been known for a long time, a lot is still unclear: The engineers want to identify suitable iron alloys that can undergo the chemical reactions as often as possible without loss. “On that basis, we want to develop the most efficient combination consisting of the best material systems and the process technology tailored to them,” project coordinator Deike explains.

The project “Me2H2 iron-steam process” comprises basic research to a large extent. Nevertheless, the final goal is to develop a concept for process and plant technology on a large, industrial scale.

The German Federal Ministry of Education and Research (BMBF) is funding the project for three years with a total of 1.3 million euros as part of the “Hydrogen Republic of Germany” ideas competition. Besides the UDE engineers, the Clausthal University of Technology and the Leibniz Institute for Materials-Oriented Technologies (IWT) in Bremen are also involved. Associated partners are thyssenkrupp Steel Europe AG and SMS group GmbH.