TU Ilmenau: New technologies for converting solar energy into green solar fuels

The Technische Universität Ilmenau is researching high-performance components and their properties in a large-scale federal project to make the production of hydrogen from sunlight more stable, efficient and cost-effective.

With the aim of expanding the climate-neutral energy supply, the Federal Ministry of Education and Research is funding the research project with 2.8 million euros over six years as part of the SINATRA funding measure. If the “SINATRA: PARASOL” project succeeds, the competitive conversion of solar energy into green hydrogen will have a wide range of potential applications in energy supply, industry and society.

Researchers around the world are looking for alternatives to conventional fossil fuels: these are not available in unlimited quantities, are harmful to the environment and are expensive. Fuels that can be produced regeneratively, cleanly and cost-effectively are the order of the day. Solar fuels, which are produced using renewable energy, make it possible to store solar energy in the form of chemical bonds, for example in hydrogen molecules, completely free of harmful carbon dioxide. Many see hydrogen as the energy carrier of the future. Hydrogen can be stored as a gas or liquid and transported in portable tanks or via hydrogen pipelines. When it reacts with oxygen, hydrogen only produces water, heat and electricity. And since it contains no carbon, no harmful carbon dioxide is produced.

Photoelectrochemical cells are regarded as the ideal way to produce solar fuels. To produce hydrogen, for example, water molecules are split into hydrogen and oxygen. This is done with the help of semiconductor-based materials: they absorb the solar energy in the semiconductor, which is converted into electrons that, just like the electrons in electricity, can move to the desired device to supply it with energy – the decisive step for generating “clean” electrical energy.

Such photoabsorbers already exist and are based on a combination of so-called III-V semiconductors and silicon, a material that ismaterial that is available in almost unlimited quantities and has almost ideal physical and chemical properties for the energy conversion process.However, these systems have a decisive disadvantage: if the III-V semiconductor or silicon comes into contact with an electrolyte, the material corrodes or even dissolves in the electrolyte. To make the system robust and reliable, the cells are coated with a protective layer and a catalyst is integrated to control the desired chemical reaction. However, even such optimized systems are only stable for a few hours, as the stability depends on the material composition of both the protective layer and the catalyst. Furthermore, both components, protective layer and catalyst, lead to additional efficiency losses.

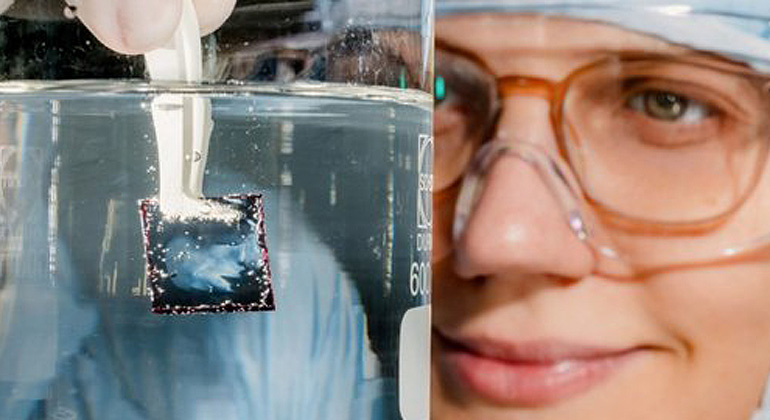

At the Institute of Physics at TU Ilmenau, one of seven junior research groups funded by the Federal Ministry of Education and Research is working on the targeted manipulation of the surfaces of semiconductors as part of the SINATRA funding measure. In the PARASOL project (“Passivation protection layers for multi-absorbers: high-performance components for the photoelectrochemical production of solar fuels”), scientists led by Dr. Agnieszka Paszuk are developing thin, stable and efficient protective layers made of metal oxides for photoelectrochemical cells.

The transitions from one material to another, the so-called interfaces, are the most critical problem for Dr. Paszuk and her team to solve. An interface is the boundary between two areas of space that are occupied by different matter or by matter in different physical states. An interface is therefore not a geometric surface, but a thin layer that has different properties from the main material on either side of the interface. The use of III-V semiconductors and passivation protection layers made of metal oxide in the components brings together groups of materials that belong to different semiconductor families. “This is a problem,” says Dr. Agnieszka Paszuk, “because an inaccurate combination of these materials results in a loss of performance when generating energy. We are now looking for the optimal material and the ideal composition, crystallinity and surface morphology of the metal oxide passivation layer. This will enable us to achieve not only stable components, but also stable charge transport in such a layer.”

In order to maximize the stability and efficiency of the photoelectrochemical cells, the research team must investigate the interface between such passivation layers and the III-V semiconductor at the atomic level. This is done at the Center for Micro- and Nanotechnologies (ZMN) in one of the largest university clean rooms in Europe using state-of-the-art technology: a combination of in situ optical spectroscopy and photoelectron spectroscopy. For stable and efficientphotoelectrochemical cells, as Dr. Agnieszka Paszuk knows, another problem must be solved: “In order to prevent the complex losses of photovoltage and the charge carrier dynamics at the critical interfaces, we have to examine the cells in contact with an electrolyte under realistic working conditions – a real challenge, but necessary in order to precisely understand the electronic states and the chemical changes at the solid/liquid interface.”

If the “SINATRA: PARASOL” project succeeds, the competitive conversion of solar energy into green hydrogen has a wide range of potential applications: Stored in large reservoirs and distributed via special hydrogen pipelines, the new technology will help stabilize the energy supply. Large-scale industrial processes will benefit just as much as vehicle drives and the various mobile and stationary applications of innovative fuel cells based on green hydrogen.