ZSW boosts efficiency of cadmium-free thin-film solar cells to world record level

Enhanced Transparency in the Blue Wavelength Range

The Centre for Solar Energy and Hydrogen Research Baden-Wuerttemberg (ZSW, Stuttgart, Germany) has managed to boost the efficiency of cadmium-free CIGS thin-film solar photovoltaic (PV) cells to 21.0 percent.

The scientists replaced the system of intermediate films consisting of cadmium sulfide and zinc oxide with a combination of zinc oxysulfide and zinc magnesium oxide to achieve this performance.

This combination promises to harvest even more light than the material used in earlier CIGS cells. With this improvement, the researchers at Stuttgart relegated their Japanese colleagues, the former record holders, to second place and took the lead in the global efficiency stakes.

The record for conventional solar PV cells made of copper indium gallium diselenide (CIGS) is 21.7 percent. ZSW scientists set this record and have now come very close to matching it with the new cell type. Prof. Michael Powalla, ZSW board member and Head of the Photovoltaics division, believes the lack of heavy metals in the new cell’s buffer layer is an advantage, but not the key benefit. The metal in conventional CIGS modules is chemically bound.

“First and foremost, the buffer layer transmits more light without the cadmium sulfide. In theory, we could use it to achieve even higher efficiency than with previous CIGS cells. The alternative buffer layer and the cadmium sulfide buffer are both deposited in a chemical bath, so a transition to manufacturing is possible without requiring additional processes,” says Powalla.

As a buffer layer, zinc oxide-sulfide is more transparent to light in the blue wavelength range. This means more sunlight penetrates to the underlying CIGS absorber layer, which then converts more light energy into electricity.

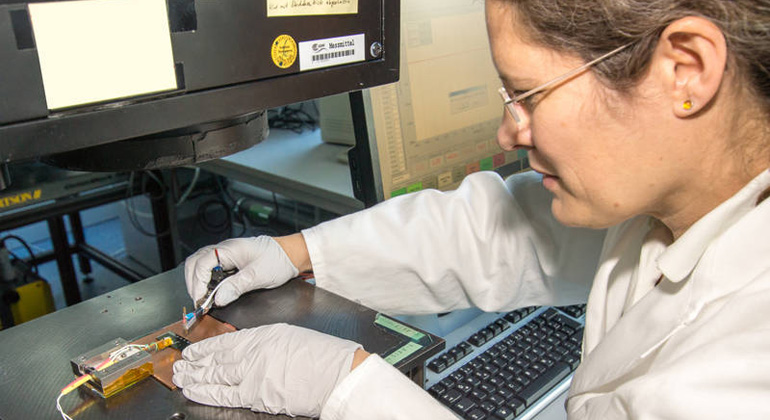

Another innovation in the cell is its improved front contact. The researchers made it with zinc magnesium oxide in place of the high resistance, thin zinc oxide film. Made in a ZSW manufacturing lab, the solar cell has a surface area of 0.5 square centimeters, a standard size for experimental cells. The Fraunhofer Institute for Solar Energy Systems ISE confirmed the results.

Alternative CIGS technology is still in the initial stages of development, so a further significant increase in efficiency is possible. ZSW’s industry partner Manz AG has already made the first test modules.

ZSW researchers expect that the modules made in southwest Germany can be brought to market within a few years.

Source

Centre for Solar Energy and Hydrogen Research Baden-Wuerttemberg (ZSW) 2015